The cross-section of the tool used is the tooth profile shape of the rack or gear, which has nothing to do with the number of teeth of the gear workpiece to be processed. One of them is made into a tool, which is used to cut the other, leaving the envelope surface of the tool edge on the gear blank to generate the tooth surface of the gear. Gear generation or generating is carried out by using the meshing principle of gear and gear or rack and gear. The forming method is generally used to repair and process single gears, and some gears with low speed and low precision requirements.

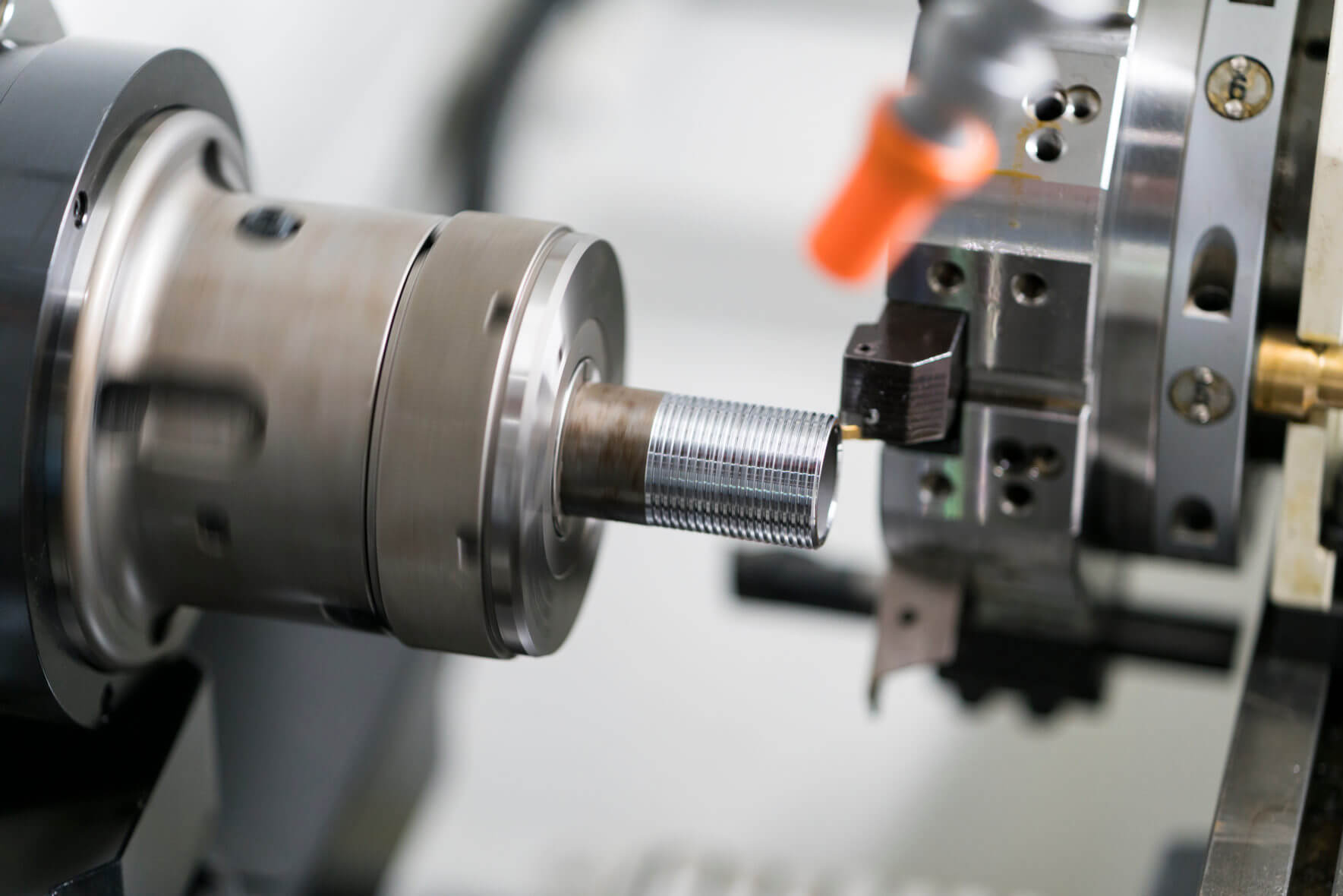

After machining one tooth space, carry out indexing, and then mill the next tooth space.

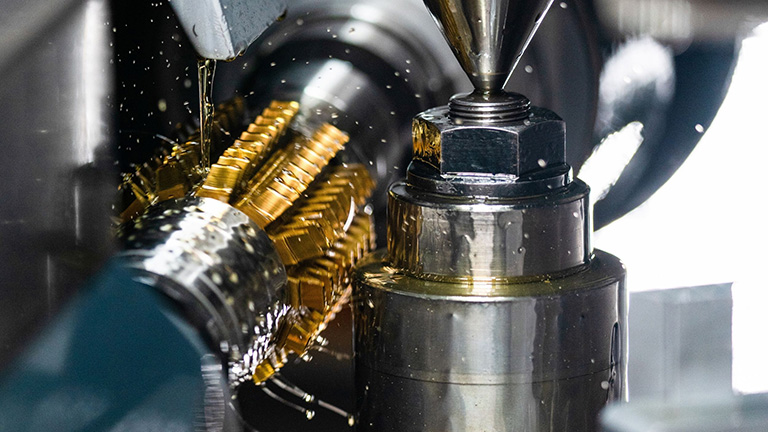

In gear forming milling, the workpiece is installed on the dividing head of the CNC milling machine, and the disc (or finger) milling cutter with a certain modulus is used to mill the gear teeth. It is only suitable for a single piece, small batch production, and repair work When using multiple tooth profiles, it has high productivity and machining accuracy, but the tool is required to have high manufacturing accuracy, complex tool manufacturing process, and high cost. When using a single tooth profile, requires a large number of tools, low machining accuracy, and low productivity. When processing with a single tooth profile forming tool, only one tooth groove of the gear is processed each time, and each tooth groove is processed successively through indexing. The profile of the cutting part of the tool used is the same as the cross-sectional shape of the gear groove to be processed.

0 kommentar(er)

0 kommentar(er)